Conversion Cost Formula & Examples What is Conversion Cost? Video & Lesson Transcript

Content

These costs thus include only direct costs and are a core part of the total product cost. This article looks at meaning of and differences between two categorizations of product cots – prime cost and conversion cost. The core cost area for a manufacturing entity is its product cost which encompasses all costs incurred in respect of entity’s manufacturing activities.

Production of combustible fuels and carbon nanotubes from plastic … – Nature.com

Production of combustible fuels and carbon nanotubes from plastic ….

Posted: Sat, 03 Jun 2023 18:08:28 GMT [source]

Most firms incur three types of costs in the production of their products. These costs are direct materials, direct labor, and manufacturing overhead. Direct materials are the actual raw materials that make up the finished product. Direct labor is the cost of the production floor workers that can be directly traced to the manufactured product.

Components of Conversion cost

However, the conversion is applicable throughout the process as what is added has to be turned into a more useable status. As we mentioned earlier, a high cost per conversion rate could mean your ad isn’t performing well. Hence, companies frequently change their marketing strategies and conduct A/B testing in an effort to improve their conversion https://www.bookstime.com/articles/conversion-costs rates. Conversion rate optimization (CRO) describes the best practices implemented by websites to optimize their conversion rates and enhance the efficiency at which sales are generated. However, if a business brings in greater site traffic, the reliance on a higher conversion rate declines, so they typically will target lower conversion rates.

Direct labor costs would include salaries, wages, benefits, bonuses, insurance, recruitment cost, training fees, pension funds, etc., paid to direct labor. Hence, using conversion costs is an efficient way of calculating equivalent units and per unit cost rather than separately calculating for direct labor and manufacturing overheads. Hence, using conversion costs is an efficient way of calculating equivalent units and per unit costs rather than separately calculating direct labor and manufacturing overheads. Here, the total cost includes beginning inventory as well as the additional costs incurred during the production process.

Why Is Calculating CPC Key for Your Business?

One way of doing this is using the Cost per Conversion formula, which allows a firm to understand how much they’re spending to convert each customer. Improve your landing page – Audiences that click on your ads end up on your landing page, and how well designed and functional your landing page is, decides whether they will convert or not. Making sure your audiences have a seamless experience, perceive value, and react to your CTAs will lead to more conversions, reducing your CPC. Evaluating Ads Timings – There are going to be certain time frames when your ads generate the most positive impressions and lead to conversions.

- Therefore, we can say that 15,000 partially complete units are equivalent to 7,500 complete units.

- If you use tools such as Google Analytics to track the traffic sources for your website, you can easily see how much traffic paid ads generate and how many of those visitors completed the desired action.

- It includes direct labor as well as any manufacturing overheads required to turn raw materials into a completed product.

- The “end goal” is determined by the company, with common examples being a customer placing an order, a user subscribing, or a sign-up for a free trial.

- Second, not all your competitors will be as proactive as this.

- Conversion costs include direct labor and manufacturing overhead.

On the other hand, overheads are indirect costs incurred during production. Indirect costs are also indispensable expenses of production, but the reason for being labeled indirect is that they can’t be directly attributed to each production unit separately. For example, the power supply or electricity required to run the machinery cannot be individually assigned to the units produced. Still, without it, the production process cannot start or continue. Other examples of overheads include indirect materials, indirect labor, rent, taxes, insurance, tools, equipment, supplies, and utilities.

Why is Cost Per Conversion Important?

The average cost per acquisition (CPA) on Facebook Ads is $19.68 across all industries. Ideally, your cost per conversion should not surpass your conversion value, as that would mean you’re paying more for a conversion than it is worth. Let’s say you run a Facebook ad campaign to promote your software.

You spent $200 on the ad campaign and gained 10 conversions. Direct labor cost is the same as it has been referred to in the above paragraphs under prime cost. As can be seen, labor is the cost that mainly determines the transformation or conversion process, then from here on there must be costs of a similar nature or of a similar impact. While it’s very natural to have a strong attachment to a particular design, how about if you alter it just a little without affecting its original purpose? It is likely to reduce costs without affecting the performance of the profit margins. According to WordStream, the average conversion cost across all industries is $48.96 for search and $75.51 for display.

What impacts the cost

Conversion costs are calculated in order to know the cost per unit, which assists the company in deciding a price for the product. To calculate cost per conversion, https://www.bookstime.com/ divide the ‘amount spent’ on running ads by the ‘number of conversions’. You’ll get the answer in your preferred currency and not in percentage.

When you consider all the conversions that take place on your website, the conversion costs can include various factors. To calculate your expenses precisely , you need to have an overview of your paid marketing initiative. If you divide the Total cost of generating traffic by the total number of conversions, you get the cost per conversion (CPC). The total cost of generating traffic includes your ad costs. After all, how else can a company know if its marketing efforts are in the right direction? Conversion cost or cost per conversion is one such marketing metric.

Conversion Cost Formula

A major stake in the expenses is acquired by the marketing and advertising function. What probably is the best part about cohort analysis is that it tracks behavior metrics of the user base for changes over fixed time intervals. This enables the business to understand a lot of things that are just impossible to interpret using averages. But what about businesses that produce digital products and services?

Though, the overheads and direct labor remain somewhat constant throughout the period. While accounting for the units of output, it becomes confusing to include partially complete units. That is why the partially complete part of work-in-process units is calculated as equivalent units—again, considering the example of XYZ Furniture Company to elaborate this concept further. Direct labor costs are the expenditures spent on factory workers directly involved in converting raw material into finished goods. For example, painters, assembly line workers, and machine operators work on the actual product. Whereas managers, policymakers, accountants, or sales staff are considered indirect labor because they are indirectly linked to the product through supervision, promotion, etc.

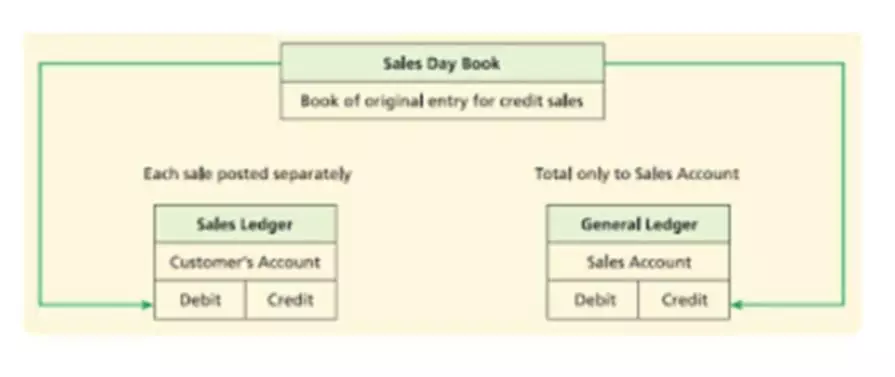

This is because process costing is the costing system used under generally accepted accounting principles for this type of manufacturer. Notice that the direct materials are not included in conversion costs. This is because conversion costs give us information on what it costs a firm to transform that raw material into a finished product. In the world of business, the use of direct labor and factory overhead costs is very common. It relates to the costs incurred during the process of turning raw materials into finished products. We are talking about indirect materials, overheads which not necessarily indirect materials or indirect labor, and also indirect materials and indirect labor.

Beginning inventory is used to calculate the average inventory for an accounting period. Cost per conversion is sometimes also referred to as cost per acquisition (CPA). In addition, mislabeling a cost not only can affect us in the current formula, but it triggers a small domino effect by not including this cost in another possible formula or ratio in which it may belong. Instead, figure out the best time to run your ads by diving into your analytics and show your ads only at these times. It depends on factors like your industry, your product or service and the type of ad campaign you’re running. Cost per conversion (CPC) is one of the easiest ways to figure out how well your ad campaigns are doing.

How to Calculate Conversion Rate

The calculation for conversion costs also includes direct labor (in addition to overhead expenses incurred as a result of the transformation of raw materials into finished products). The firm wants to figure out the conversion costs so they can adjust prices for next year. The frames and lenses are direct materials and are not included in conversion costs. The $200,000 paid to production workers is direct labor, which is a conversion cost. The $50,000 paid to the production manager is manufacturing overhead, which is a conversion cost. The $200,000 cost for renting the production facility is part of manufacturing overhead costs, which are conversion costs.

How do you calculate conversion costs?

Conversion costs are calculated by simply adding up all direct labor costs and manufacturing overhead costs. Direct labor costs are the labor costs that can be directly traced to a product.